Manufacturing Problem Solving: Efficiency & Waste

At Moffitt, we don’t see our factory crew as assembly people, we see them team members. We take this view because we challenge them to look at their jobs as manufacturing problem solving. We want them to always ask “how do I make this process faster?” Or “How do I make my jobs safer?” Or even, “How do I make this task simpler?” By having our crew ask these questions, and by empowering them to find the answers, we can improve efficiency and reduce waste to pass savings along to our customers.

In manufacturing inefficiency and waste lead to lost time. We all know the expression “time is money”, and there is no where that it is more clear than in manufacturing. When the team is comfortable with waste, then that means money is just waltzing out the door. Soon after that, jobs start to waltz out the door too. You can prevent this by first reducing waste and then improving efficiency.

Reduce Waste

In manufacturing waste is everything in the factory that doesn’t add value to the process. This waste fits into 8 categories.

- Inventory – Making more than customers’ demand leads to unnecessary stock. These products get in the way of other processes and run the risk of being obsolete and unsellable. Only produce what is ordered to reduce excess inventory.

- Transportation – Moving tools, materials, parts, etc. from one location to another. It is important to transport stuff quickly, safely, and efficiently. Not having the right equipment, or having to wait for the right equipment, will lead to delays.

- Motion – Extra walking, bending, or moving to reach commonly needed items. Frequently used items should be at point of use. Keeping tools and other equipment in convenient locations reduces unneeded movement. This speeds up the process and reduces exhaustion.

- Waiting – Delays between processes, machines, etc. Idling the next stage by a delay in your stage slows down the entire process.

- Over processing – Duplicate processing and redundant operations slow down the process. Think about what you need to do the job and how the process can be more efficient.

- Defects – Rework, scrap, customer quality complaints. This one is literal waste. If the finished product is junk it must be thrown away. Reducing defects is one of the key components of reducing waste.

- Skills – Underutilized skills and capabilities, not listening, not changing. A smart worker always looks to see how he or she can improve the job. Fostering employee growth, taking feedback, and assuming new responsibilities will reduce waste. An employee may be great at one process but even better at another with a little training. It could be hard to lose them, but it would be wasteful not to utilize them to their full potential.

Improve Efficiency

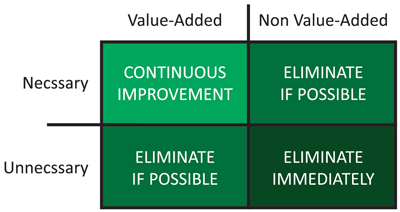

Now that we’ve isolated potential wastes the next step is to see how we can prevent them. The best way to do this is to look at the 3-S method.

- Sort

- Set in Order

- Shine

This is a productivity tool to help everyone eliminate clutter to focus on value added activities and improve workflow. By splitting things like tools into groups (sort), putting them in their proper places (set in order), and keeping them in proper working condition (shine) we can improve the entire process.

The goal is to organize the workspace in a way that allows work to flow without extra effort (see Motion and Waiting above). Work does not flow smoothly when you must stop and search for things. For example, don’t put a tool that you use with your right hand on the left side. It may seem like a small thing, but small inefficiencies add up.

Engineering the Process

By focusing on inefficiencies and reducing waste we established an engineered, repeatable process. Analyzing the situation makes abnormalities visible and helps streamline the process. This is done through big actions like evaluating personnel to small actions like promoting cleanliness. This is all part of problem solving in the manufacturing environment.

The main Moffitt factory, Moffitt West, implements these manufacturing problems solving practices daily. This factory has been in operation for decades by principles such as these into practice. That is what makes Moffitt the Natural Solution for ventilation.