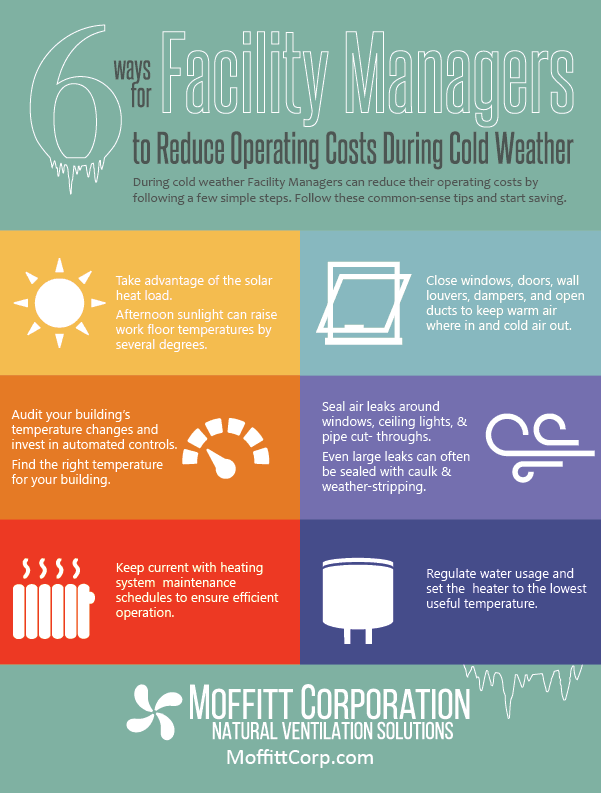

6 Ways Facility Managers Reduce Operating Costs

There are many ways to control heating costs in a large industrial facility during the winter. Aside from the large building improvements or capital investments, there are many simple and low-cost measures you can take that will also help you reduce operating costs.

Reduce Operating Costs During Cold Weather

Below is a list of 6 ways to reduce operating costs and prevent energy loss provided by the U.S. Department of Energy. These tips are focused on the home, but we’ll explain how they can be adapted for a workspace like a factory or a warehouse and how implementing them can help you save.

- Take Advantage of Heat from the Sun; Open curtains on south-facing windows during the day. This will allow sunlight in and naturally heat your home. Don’t forget to close them at night. This will reduce the chill from the cold night air.

Likely, your plant doesn’t have a lot of curtains. However, using solar shading or louvered shutters is the same principle. It may seem insignificant but depending on where the windows are located afternoon sunlight can raise work floor temperatures by several degrees. Natural lighting through a roof vent can also have an enormous impact. The heat from the sun will warm up a plant faster than the heat from several lights.

- Adjust the Temperature; When you are home, set your thermostat to the lowest possible comfortable temperature. When not at home, or asleep, turn the thermostat down about 10° to 15°. If this is done for eight hours a day you can save around 10% a year on heating. A programmable thermostat makes it easy to set temperatures ahead of time.

This tip probably isn’t news to anyone. Adjusting the heater to only heat occupied space is an obvious move. If your heating controls aren’t programmable, getting a new one should be a moderate expense. Find temperatures that work best for you and your crew.

Duct drops are a larger expense to be sure, but having overhead vents blow warm air directly to where you need it can make a huge difference in temperature control. Instead of trying to heat a whole warehouse, heat only key workstations.

- Cover Drafty Windows; Heavy-duty, clear plastic sheeting or clear plastic film on the inside of window frames, can help keep the cold air out. Put them on during the cold winter months and remove them when it gets warm again. Tighten the plastic seal to prevent infiltration.

Unused windows or doors, or exposed duct openings that are no longer in use, should be sealed tightly. Covering these up will help prevent heat loss. Of course, many factories have large open bays like truck doors or roof vents that are needed for smoke exhaust. Options are limited in these situations.

- Find and Seal Leaks; Seal air leaks around pipe utility cut-throughs, gaps around chimneys, gaps around ceiling lights.

We can not overstate the importance of finding and detecting air leaks. Visual inspections, thermal cameras, and pressurization tests are all helpful ways to find air leaks. Caulk or other door weather seal methods and weather stripping are often enough to seal even relatively large air leaks around leaky doors and windows.

Truck bays, doors, and roof vents may have poor seals or no seals by design or by wear and tear. Look for options that do include insulation and make sure you keep up maintenance on these areas. For roof vents, consider dampers that can be closed when the smoke release isn’t a problem or for when you want to keep heat inside of the building.

- Maintain Your Heating Systems; Schedule service for your heating system. Find out the schedule for maintenance required for your system, and keep to it to ensure your heating system is operating efficiently.

Whether it’s a small HVAC unit or a large direct-fired heater, keeping up on maintenance is important. Making sure internal components are clean and in good shape goes a long way towards efficiency. Catching wear before it becomes a break can make the difference between a small repair call and a frozen building with an emergency. If your HVAC unit is due a service or repair contact the professionals and explain what you need doing. Make sure you try and find a company that operates locally to where you live too.

- Lower Your Water Heating Costs; Water heating can account for as much as 25% of home energy consumption. Turn down water heater temperature to around 120°F to save energy and reduce costs. You can also save energy and costs by finding a more efficient water heater for your home.

This advice works just as well for facility management as it does for a home. Setting your water heater to a reasonable temperature can help with costs in the long run.

6 Ways Facility Managers Can Reduce Operating Costs

These 6 energy saving tips are just a few ways to see some quick and easy cost savings. Lowering energy bills in a large facility can be a massive undertaking, that it is why it is always a good idea to perform an annual energy audit and plan ahead. Evaluate the problem areas and see how they might be impacting your total operating costs. Moffitt Corporation can help with controlling the temperature inside of your building all year long. Contact us today to learn more about how to keep your building warm in the colder months.