CFD Modeling for Ventilation

For over sixty years Moffitt has designed ventilation solutions for heavy commercial and industrial facilities of all shapes and sizes. While technology has changed significantly in that time, the principles of ventilation haven’t changed. Exhausting hot air, bringing in cool air, and improving the overall rate of airflow have been the goals of ventilation since the time of the caveman. Now however, with tools like CFD modeling, ventilation systems can be designed much more quickly, precisely, and efficiently.

CFD Modeling for Ventilation Solutions

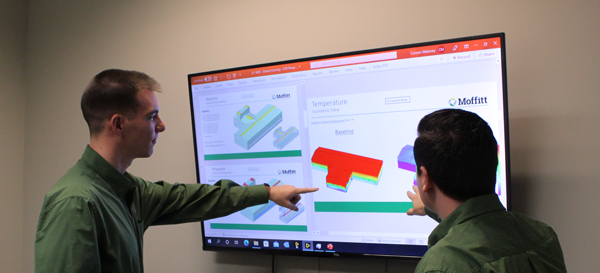

Computational Fluid Dynamics (CFD) is a branch of fluid mechanics that uses advanced mathematics and physics to solve problems that involve different fluid flows. At Moffitt, we utilize CFD modeling to track, illustrate, and assess air flow within a building. We look at how air moves throughout the building, and then compare that to how the air will move with a new ventilation solution.

These models allow us to test different ventilation options through an iterative process. Sometimes modeling shows us that more vents are needed, or that they need to be located further towards the end of the building. Other times, a model will show that extra air intake is required. Ultimately, we can find the perfect solution for a given facility through CFD modeling.

As a result, we no longer need to wait until we install the equipment to see the results. Now we can measure airflow and temperature changes before the new system is even fabricated.

Find the Right Ventilation for Your Building

Buildings of all sizes, scopes, and industries can benefit from CFD modeling. Heavy industrial facilities that produce a lot of heat, like smelters or glass plants, use CFD models to determine how they can exhaust the most hot air from the building. Lower heat facilities, like paper mills, data centers, and manufacturing facilities, use modeling to increase air changes and maximize airflow.

CFD analysis removes a lot of the guess work from the ventilation design process. For example, instead of just telling a customer that their building will be cooler, we can pinpoint exactly where it will be cooler and by how much. We can also show them how the temperature might change at different heights of the building and throughout the year. Best of all, we can show you which equipment solutions will yield the best possible results. Through detailed, full-color models you can rest assured that you’re getting the right ventilation solution for your facility.

Our design engineers will improve airflow, lower temperatures at certain elevations throughout the building. They will also consider special conditions such as closed bay doors. Furthermore, they can adjust for seasonal temperature changes and show you what conditions look like in the middle of summer. These options will let you better choose the right system for your needs and budget based.

Our Experience with CFD Modeling

Moffitt has been developing CFD models for ventilation solutions for over a decade now. In that time, modeling has become faster, more efficient, and more reliable. Additionally, the models have become more detailed and allow us to analyze more variables. Our CFD engineers work hand in hand with our Salespeople, Project Engineers, and Design Engineers. Together, they develop innovative solutions for our customers’ building ventilation systems.

Contact Moffitt today to learn more about our CFD modeling solutions.