How Long Can a Factory Worker Work in High Temperatures?

All too often new customers push back on a new solution because they say that ventilation doesn’t make them money. It’s easy to see the return on investment for a new machine, but it’s harder to see how improving airflow will help. However, we’ve seen time and again how a new ventilation solution can save you money by increasing productivity and reducing employee turnover. You don’t have to take our word for it, we’ve done the math to answer the question; How long can a factory worker work in different temperature buildings.

How Decreasing Temperatures Increases Productivity

Section III: Chapter 4 of The Occupational Safety and Health Administration (OSHA) technical manual it outlines Heat Stress and how to prevent it [1]. OSHA defines heat stress as “The net load to which a worker is exposed. Physical exertion, environmental factors, and clothing worn all contribute to heat stress.” When exposed to a high amount of heat stress the human body reacts negatively, resulting in reactions such as heat stress, exhaustion, and in extreme cases death. This stress is what leads to decreased productivity and employee turnover. OSHA recommends scheduling work to happen early or late in the day, and acclimatizing workers to the heat, using a work/rest schedule and having relief workers step in when needed.

In an industrial facility, it can be difficult (if not impossible) to enact all these suggestions and still meet the production targets. Not every plant can work around the clock, so early mornings and late nights are often off the table. So, let’s look at the effectiveness of acclimatization and implementing a work/rest schedule supplemented by relief workers.

First, acclimatization means that the body temporarily adapts to their surrounding conditions the longer they are exposed to it. Basically, workers get used to the heat the longer they are exposed to it. Within a couple of weeks, a new hire can work efficiently in a building that felt unbearable when they started. Of course, even then you will encounter safety issues and require breaks.

How Long Can a Factory Worker Work Without a Break?

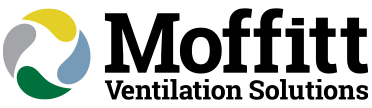

So, let’s look at Chapter 32 of the ASHRAE HVAC Applications Handbook to see how long a worker who is already acclimatized to the heat in a facility can work without a break. The chart is in Figure 1:

The dashed lines on this graph indicate at what point of work intensity and Wet-Bulb Globe Temperature does the work/rest ratio apply. The Wet-Bulb Globe temperature (WBGT) indicates the “heat related stress on the human body at work” [3]. Equation 1 is used to calculate the WBGT inside a facility by using the Heat Index [4]:

WBGT = [(-0.0034(HI)2 + 0.96(HI) – 34) × 9/5] + 32

In Equation 1, HI represents the Heat Index and WBGT represents the Wet Bulb Globe Temperature. The following is an example scenario that illustrates how to identify the work/rest ratio in a facility. Read on to answer the question “how long can a factory worker work in high temperatures”?

Working in a 120°F Factory

For an average factory, the heat index in one of the hottest areas of the plant may be 120°F. Using Equation 1, we can calculate the following:

WBGT = [(-0.0034(120)2 +0 .96(120) – 34) × 9/5)] + 32

WBGT=90 °F

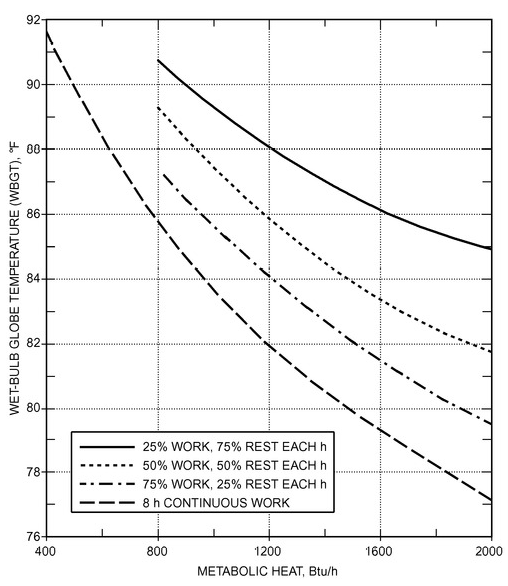

Using the work/rest ratio graph provided by ASHRAE, the following line is plotted in Figure 2:

Based on this info, we can determine that at minimal intensity (i.e. sitting at a desk) an acclimatized person can work for a continuous eight-hour period without mandatory breaks (indicated by the blue cross mark).

However, if a worker is performing even light work, they must rest for 75% of an hour, after working 25% (indicated by the red cross mark). That means that a worker can only work safely, let alone efficiently, for fifteen minutes at a time. Then, they must take a forty-five-minute break just to get back to normal. As a result, you must cycle four employees every fifteen minutes for one productive hour.

Is the above scenario cost effective? Absolutely not. However, if you reduce the WBGT (temperature) in that section to a level that increases allowable work time and decreases necessary break time. This provides a boost in productivity and a huge cost savings.

Working in a 100°F Factory

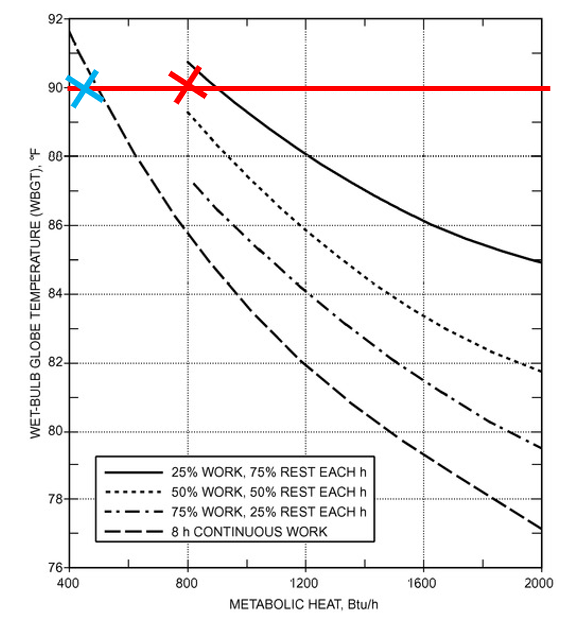

A better ventilation solution can reduce temperatures significantly. Let’s say you invest money into improving the ventilation in your facility. You purchase and install some exhaust fans on the roof and supply fans on the wall. These will help remove the buildup of hot air and steam and bring in fresh, outdoor air. The new heat index of 100 °F (That’s a 20 °F improvement in “feels-like “temperature). You use this value to calculate the new WBGT in the same location:

WBGT=[(-0.0034(100)2 + 0.96(100) – 34) × 9/5] + 32

WBGT= 82.4 °F

Finally, plotting this new WBGT on Figure 3, we see a significant improvement in work time. The acclimatized workers can now perform eight hours of work without mandatory breaks to prevent heat stress.

The 20°F Difference in Your Factory

In conclusion, workers in the ventilated area will feel twenty degrees cooler with the new ventilation system. Employee morale will improve too, as they will be able to feel the difference in temperature at their workstation. Of course, it also means that one person can do a full hour’s worth of work instead of four.

Productivity on the floor increases, turnover rates decrease, and the required number of workers is reduced. All with the investment in improving the plant’s ventilation system.

So how long can a factory worker work in a hot environment? It all depends on exactly how hot it is.

A new ventilation solution will help you improve productivity in your industrial facility. Plus, the long life and the efficiency of the equipment also makes investing in ventilation cost effective. Not only will this minimize downtime and reduce turnover, but it will also enable employees to work without fear of heat stress or injury.

Works Cited for How Long Can a Worker Work in High Temperatures

| [1] | Occupational Safety and Health Administration, “Heat Stress,” Occupational Safety and Health Administration, 15 September 2017. [Online]. Available: https://www.osha.gov/otm/section-3-health-hazards/chapter-4#illness_prevention. [Accessed 8 February 2024]. |

| [2] | American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., “Chapter 32. Ventilation of the Industrial Environment,” in ASHRAE HVAC APPLICATIONS, Atlanta, American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., 2019, pp. 764-776. |

| [3] | National Weather Service, “Wet Bulb Globe Temperature vs Heat Index,” National Weather Service, [Online]. Available: https://www.weather.gov/ict/wbgt. [Accessed 8 February 2024]. |

| [4] | I. I. Thomas E Bernard, “Heat index and adjusted temperature as surrogates for wet bulb globe temperature to screen for occupational heat stress,” J Occup Environ Hyg, pp. 323-333, 2015. |